HEADON

- ANTY S.r.l.

- Mar 31, 2022

- 1 min read

Helpful: when a fixed machine with high productivity is needed for the tilting of boxes from the floor at the start of the transformation line, where the spaces do not allow the forklift to arrive.

Robust: a solid structure and mechanisms located in the protected area guarantee longevity even from accidental impacts of moving vehicles. 380 V electro-hydraulic control unit for industrial use.

Safe: active and passive safety thanks to side protection cage, photo-electric cell control, descent with "parachute" valve, automatic body locking and unlocking. Unloading hopper in decontaminated stainless steel, passivated, ASTM certified.

Flexible: can be interfaced with all forklifts (helm or manual) and boxes

Easy: hanks to its stability it avoids floor fixing interventions, simplifying the installation and any subsequent displacement.

Tailored: Body tilting side can be customized on the long or short side.

HEADON

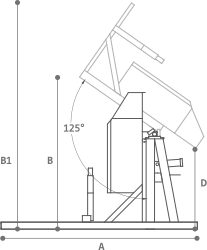

Distinctive characteristics Fixed floor-mounted equipment for tipping and emptying bins at the chosen height.

Unloading angle (°) 120

Static capacity (kg) 600

Independent hydraulic controls 1

Materials - Structure in non-alloy steel (S355JR) - Unloading hopper in Inox

Finish Painted

Options On request you can have tippers with unloading height 350 mm and 450 mm. Customizable tipper side in the factory on the long or short side.

RPT1300

Weight (kg) 450

Packaging 2830 x 1500 x 1700 Peso: 600 kg

RPT600

Weight (kg) 400

Packaging 2400 x 1500 x 1550 Peso: 450 kg

RPT1300

(A) Length (mm) 2800

(C) Width (mm) 1500

(B) Minimum Height (mm) 1960

(B1) Minimum Height (mm) 3300

(D) Unloading Height (mm) 1250

RPT600

(A) Length (mm) 2290

(C) Width (mm) 1500

(B) Minimum Height (mm) 1400

(B1) Maximum Height (mm) 2400

(D) Unloading Height (mm) 580

Comments